The Internet of Things (IoT) Projects on Industrial Automation: Key Concepts and Applications technology has transformed industrial automation. Industrial automation aids in the efficient and safe connection of machines, sensors, and other devices by the IoT. This paper takes up key concepts of IoT-based industrial automation, which are explored through common components and applications appropriately optimized for relevant keywords and products.

Table of Contents

- Key Concepts in IoT Applied to Industrial Automation

- Key Components for IoT Automation Projects

- Applications of IoT in Industrial Automation

- Conclusion

Key Concepts in IoT Applied to Industrial Automation

1. Real-time Data Monitoring – Internet of Things (IoT)

IoT enables real-time monitoring of data from sensors and machines, thus allowing industries to continually monitor the processes, which leads to decision-making based on data. For instance, through the HC-SR04 Ultrasonic Sensor Module, distance among the objects in an automated environment can be measured, thus ensuring that the machinery operates within safety parameters.

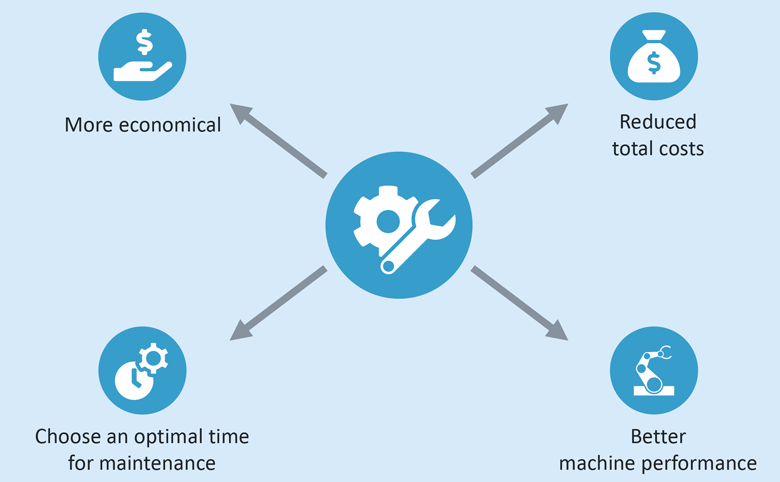

2. Predictive Maintenance

Predictive maintenance is a must for IoT technology as information from machines provides insights to analyze problems before they turn into breakdowns. The whole system can keep monitoring movements, with sensors such as the HC-SR501 PIR Motion Detection Sensor, and detect potential mechanical anomalies, which are therefore less likely to cause downtime.

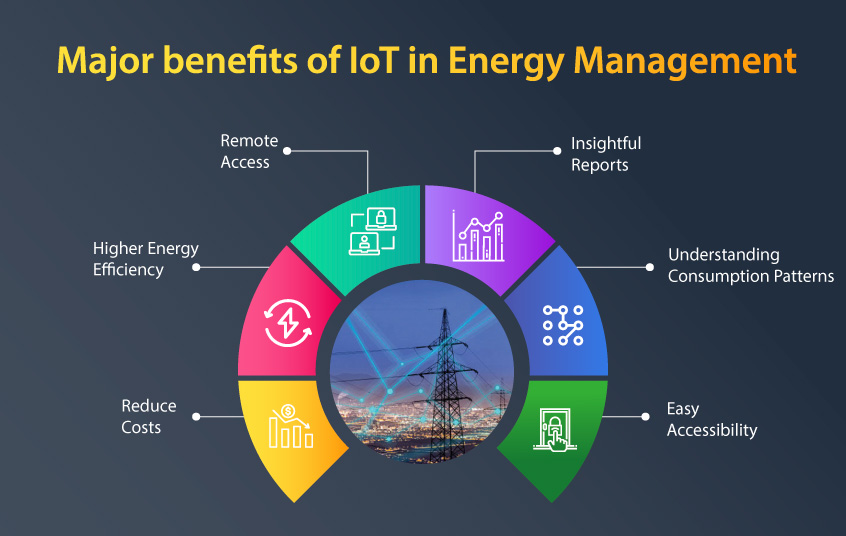

3. Energy Management

IoT-based automation helps save energy by recording energy consumption data. Many parts of it, like 74LS194 – 4-bit Bi-directional Shift Register IC, are responsible for managing almost all devices and even for industrial facilities to work without wasting much energy.

4. Remote Monitoring and Control

The most important advantage of IoT in industrial automation is remote machine monitoring and control. Developed on an Arduino Uno R3 Development Board, with the ESP8266 NodeMCU Wi-Fi Module, a system can be connected to cloud-based platforms for transference of data, allowing operators to control operations from anywhere around the globe.

Key Components for IoT Automation Projects

Precise and reliable components play an important role for the successful implementation of IoT in industrial automation. Some of the crucial IoT components that can be implemented in automation systems include the following:

- Arduino Uno R3 ATmega328P Board: It is one of the essential development boards forming the basis of many IoT projects. It is robust about providing compatibility with a variety of sensors and modules. This board is applied for control of automated machines or for real-time reading of sensor data.

- 16×2 LCD Display (Green Backlight): In an industrial context, interconnected displays are particularly crucial in keeping track of working parameters such as temperature, pressure, or status of equipment for observation.

- 5V 10A Relay Module: A relay module is used to control high power industrial equipment, which may help people automate heavy machinery by being able to turn the machines on and off.

- Servo Motor SG90: Servo motors are used in the control of a robotic arm or conveyor belt to make way for precise movement and positioning in industrial tasks.

- HC-SR501 PIR Motion Detection Sensor: Motion detection in the industry is useful for security and energy management as it enables an action in triggering whenever motion is detected in unauthorized areas.

Applications of IoT in Industrial Automation

1. Smart Factories

Smart factories provide highly automated environments through IoT systems, which connect machinery, workers, and software. This enables engineers to easily program microcontrollers using Arduino Uno Mega Programming Cable for collecting data from sensors, including PIR Motion Sensors and Temperature Sensors, that will give an upper hand in the seamless automation of processes in a factory.

2. Supply Chain Automation

With the integration of IoT devices, such as this IR Sensor Module – LM393, it can ensure that the logistics for a company’s supply chain were streamlined along with inventory tracking and warehouse automation. In this regard, businesses are able to make decisions faster and more intelligently with real-time data.

3. Energy Efficiency Systems

Applications in the management of energy are IoT applications related to the control of devices such as 5mm LDR, which is used to monitor the lighting system installed in a factory. These sensors then detect the level of light in the ambient while automation systems adjust lighting or HVAC systems, saving energy.

4. Robotics and Automation

Production will always be revolutionized by the power of IoT. Using a robotic arm or conveyor system with its motor controlled by an L298N 2A Based Motor Driver Module, engineers can ask it to accomplish those tedious tasks with much more precision and minimal human intervention.

5. Machine Learning / AI Integration

IoT devices can even analyze huge amounts of data when they are integrated with AI. For example, an A3144 Hall Effect Sensor can detect magnetic fields or can use the input for machine learning models to predict machinery failures or optimize processes.

Automation of industries through IoT is transforming the face of doing business to make it efficient, safe, and sustainable. It can range from monitoring energy usage to predictive maintenance for that factory. With components like the Arduino Uno R3 Development Board, HC-SR04 Ultrasonic Sensor Module, and 5V 10A Relay Module, it is quite possible to create very automated systems which ensure long-term success in operation.

Integrating these modules within projects increases productivity and lets the doors open to technologies like AI and machine learning for future-ready industrial automation.